Label & Ribbon Guide

This handy guide will help you to understand the differences between thermal transfer and direct thermal labels and how to tell them apart.

Which ones do I need?

The simplest way to determine which type of labels you need is to refer to the printer they will be used in. If it is fitted with a ribbon then you need Thermal Transfer labels. If your printer does not use a ribbon then you will need Direct Thermal labels. Internet Labels however sell printers which can work with or without a ribbon. This gives you more choice allowing you to use labels most suitable to the job in hand, and provides extra future proofing of your purchase decision. It will however mean that you need to decide which label type is best suited to your requirements.

Thermal Transfer

Thermal transfer labels require your printer to be fitted with a ribbon and it is the ink from this ribbon which is transferred using heat from the printhead to create dark and vibrant print with a long lasting finish. Various label and ribbon combinations can be used to cater for standard carton labelling to mission critical serial number labels to withstand extremities of use. Our ribbons also have a special smooth coating to minimise printhead wear, extending the life of this expensive component.

Direct Thermal

Direct thermal labels do not use a ribbon. Instead the surface is coated with a heat reactive layer which turns black when in contact with the heat from the printhead. This reactive surface will effectively cause the print to fade when exposed to sunlight, strong artificial light or indeed friction (cartons rubbing together during transit for instance) with the speed of fading dependent upon the intensity of the light or friction. For this reason direct thermal labels tend to be used for short shelf life products such as fresh food. Although there are no ribbon costs associated with direct thermal labels there are other cost increases involved as without the ribbon acting as a protective insulator between the printhead and the label, the printhead will wear more quickly requiring more frequent replacement.

I have a label in front of me, how can I tell what type it is?

It is quite easy to tell. Take a ruler or other item with a hard edge (a long finger nail will do, if you have them) and run it quickly across the surface of the label using medium pressure as if you were trying to score the surface. Try a few times using more pressure each time but without trying to tear the label, or break your ruler or a nail! A direct thermal label will develop black lines whereas a thermal transfer label will only show some slight self coloured "rub" marks.

How does that work?

Dragging the item across the Direct Thermal label creates friction and therefore heat. Heat is what reacts with the Direct Thermal label surface to create the black marks, which are cleverly controlled by the printer to create your printed label. It is worth noting that heat from friction (products rubbing together in transit) strong light (including sun light) and heat from possibly radiators, spot lights, machinery etc. can all have a detrimental effect on a Direct Thermal label, which is why they are only recommended for short life labelling requirements

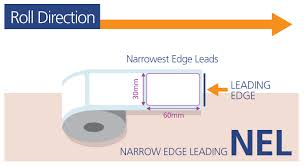

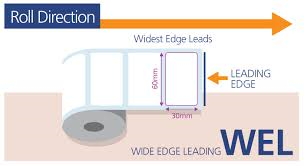

Leading Edge (Direction off roll)

The direction in which the labels come off the roll can be one of two ways:

Wide edge leading. This means the longest edge of the label will always be first off the roll. For example a label sized 30mm x 60mm in wide edge leading configuration would have the 60mm edge first off the roll for every label. Similar to a "landscape" view when facing the labels as they come off the roll.

Narrow edge leading. This means the shortest edge of the label will always be first off the roll. For example a label sized 30mm x 60mm in narrow edge leading configuration would have the 30mm edge first off the roll for every label. Similar to a "portrait" view when facing the labels as they come off the roll.